Thermal System

UHT, Pasteuriser and Aseptic Tank

To meet the challenges present in the food and beverage industry head on, you need a partner with deep understanding of process engineering and a broad portfolio of equipment. APEQ Process provides professional thermal systems aimed to kill micro-organisms in products, and at the same time maintain the natural flavour and appearance of end products.

Having in-depth application knowledge and a dedicated program of development and innovation, APEQ Process is your best choice in helping to drive thermal processes of your plant. APEQ Process's thermal system comprises of the following:

UHT Treatment

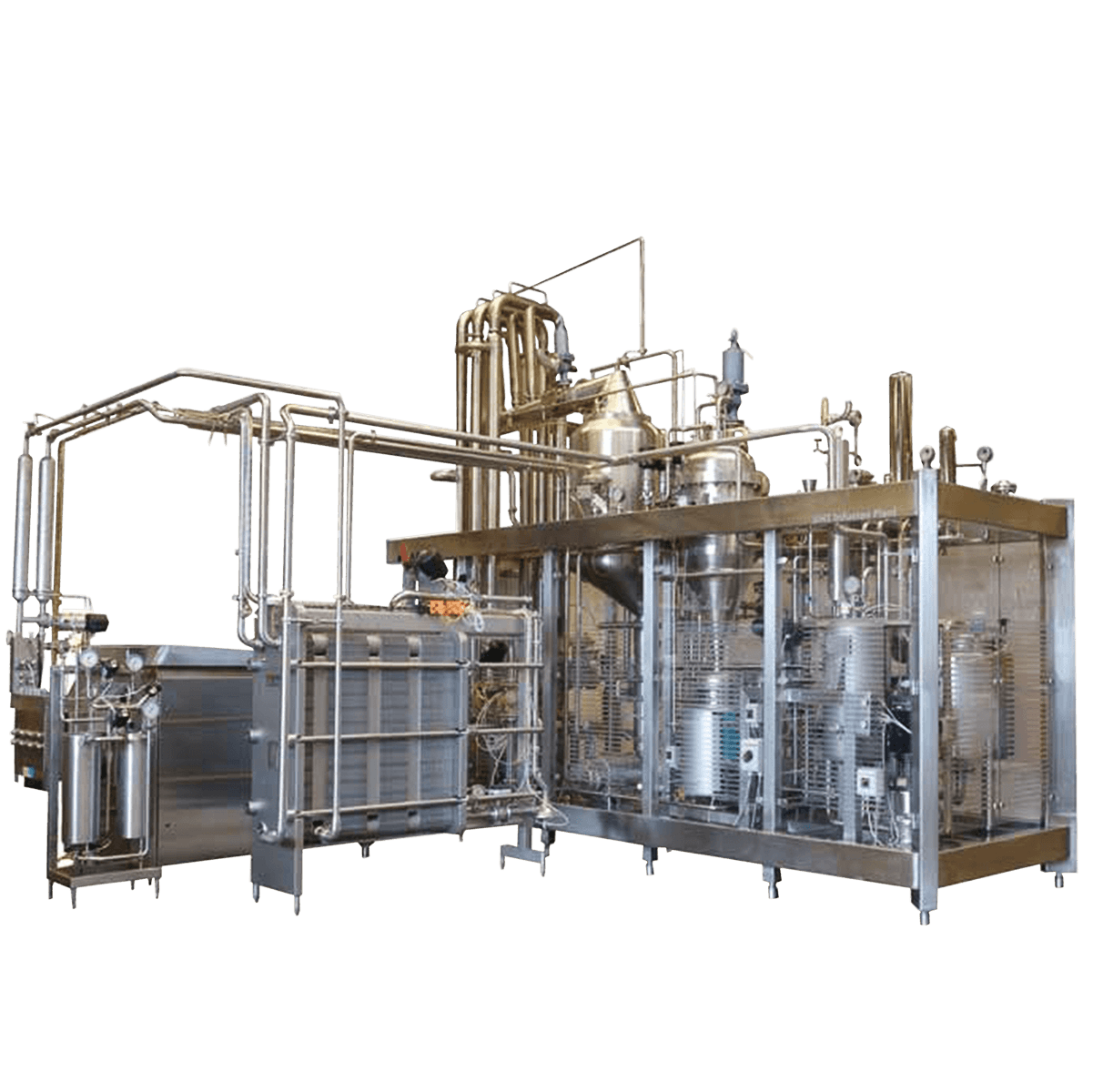

Infusion UHT plant - SDH

A UHT plant designed for very fast heat treatment, with an efficient bacteria spore kill rate and a very low chemical change to the product. Often named the most gentle UHT treatment on the market.

The infusion technology ensures rapid and controlled heating of the product, where the short holding time ensures product quality and freshness.

The advantages of a SDH Infusion UHT plant include:

- Gentle and accurate heating in the infusion system

- Fast heating 600°C/sec

- Accurate holding time

- Superior product quality

- High product flexibility

- Low fouling rate

- Long operating time between CIP

- Operator-friendly, pre-assembled and factory-tested

- Gentle and accurate heating in the infusion system

- Fast heating 600°C/sec

- Accurate holding time

- Superior product quality

- High product flexibility

- Low fouling rate

- Long operating time between CIP

- Operator-friendly, pre-assembled and factory-tested

Injection UHT plant - SDI

A UHT plant designed to give a very fast heat treatment, with an efficient bacteria spore kill rate and very low chemical change to the product.

The advantages of a SDI Injection UHT plant include:

- Gentle and accurate heating in the infusion system

- Fast heating 300°C/sec

- Superior product quality

- High product flexibility

- Low fouling rate

- Long operating time between CIP

- Operator-friendly, pre-assembled and factory-tested

- Gentle and accurate heating in the infusion system

- Fast heating 300°C/sec

- Superior product quality

- High product flexibility

- Low fouling rate

- Long operating time between CIP

- Operator-friendly, pre-assembled and factory-tested

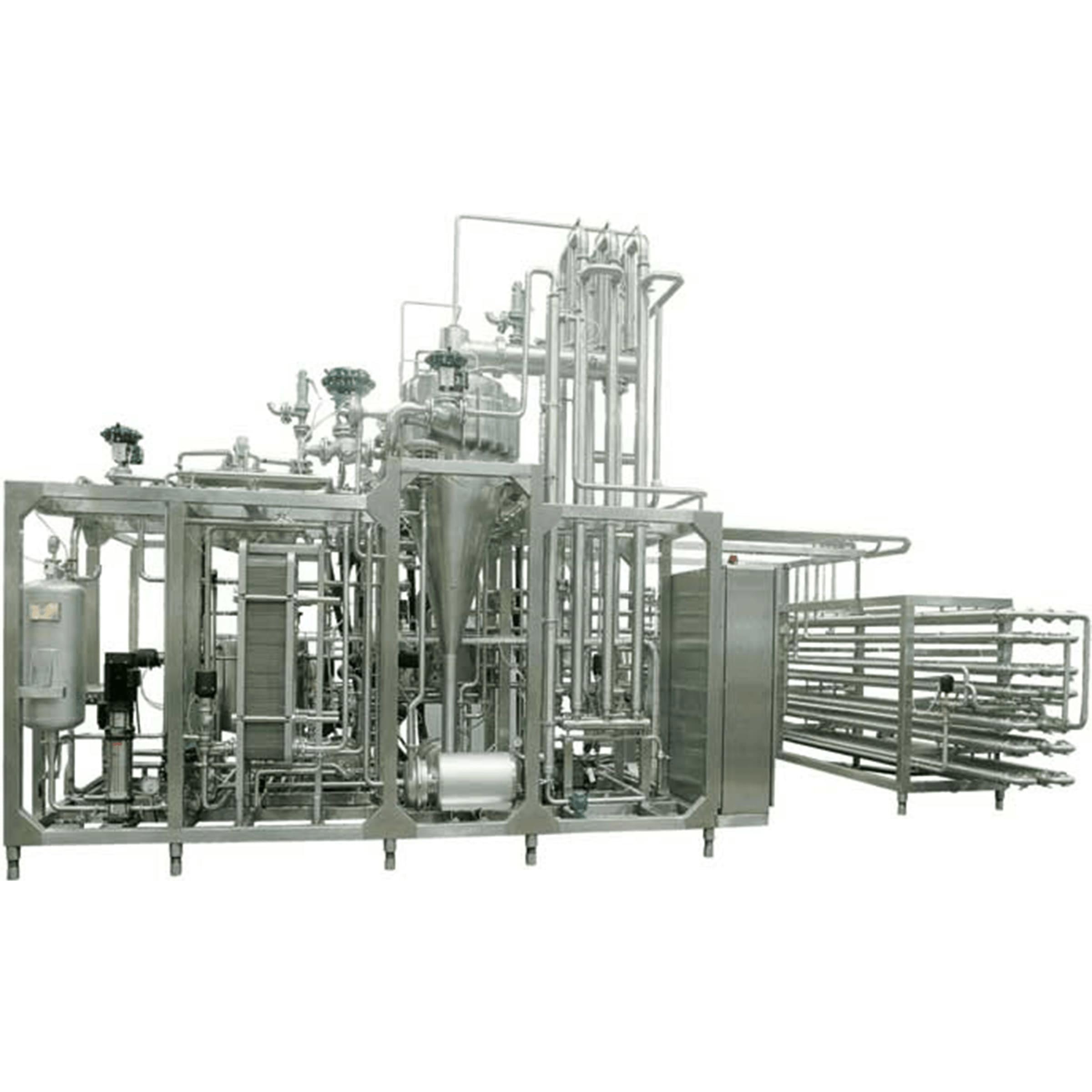

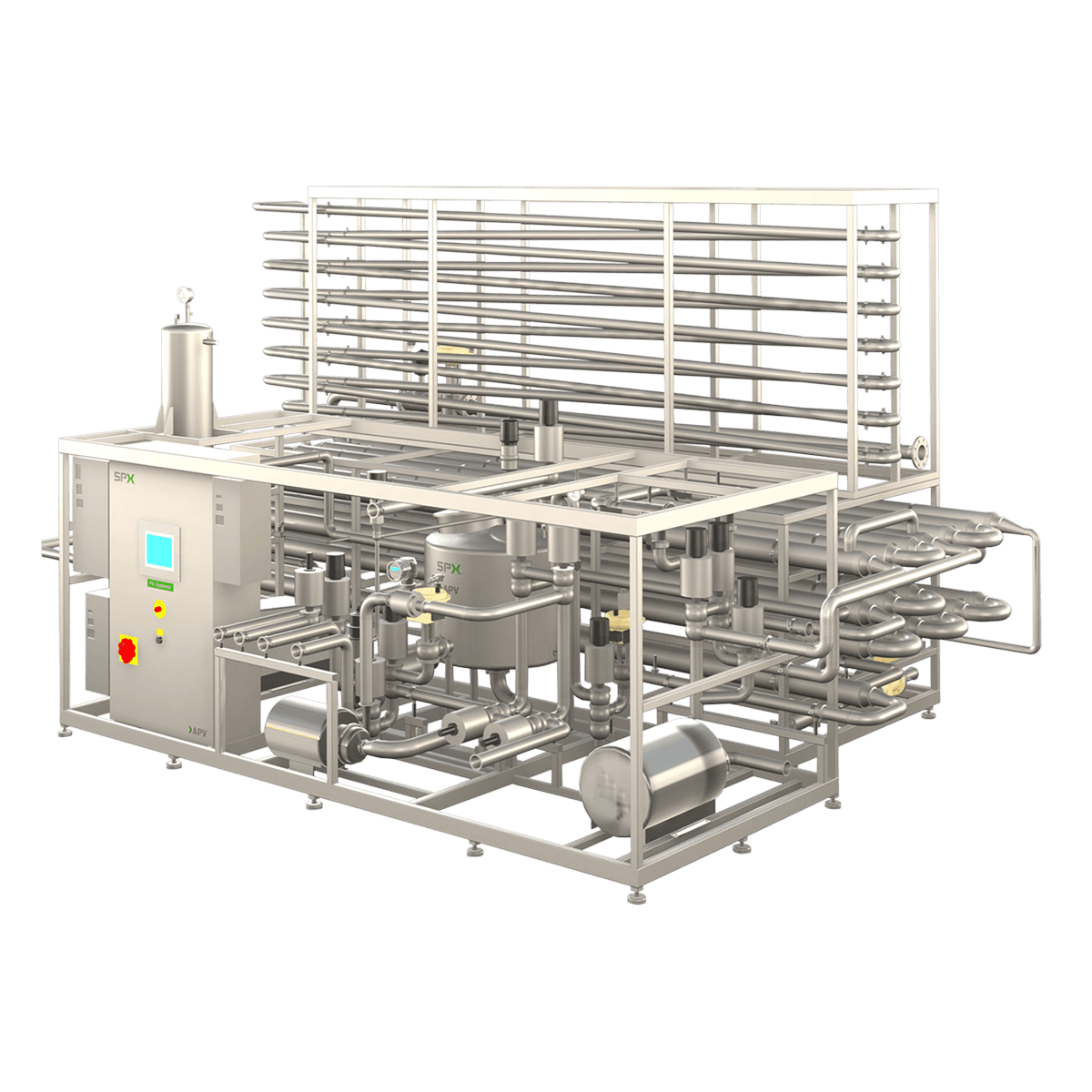

Tubular UHT plant - STH

Robust and flexible UHT plant. Back pressure tolerance up to 60 bar and heat regeneration of approx. 85%.

The advantages of a STH Tubular UHT plant include:

- High up-time

- Flexible product range

- Easy inspection of product and medium surface

- High pressure tolerance

- Low energy cost

- Low maintenance cost

- Operator-friendly, pre-assembled and factory-tested

- High up-time

- Flexible product range

- Easy inspection of product and medium surface

- High pressure tolerance

- Low energy cost

- Low maintenance cost

- Operator-friendly, pre-assembled and factory-tested

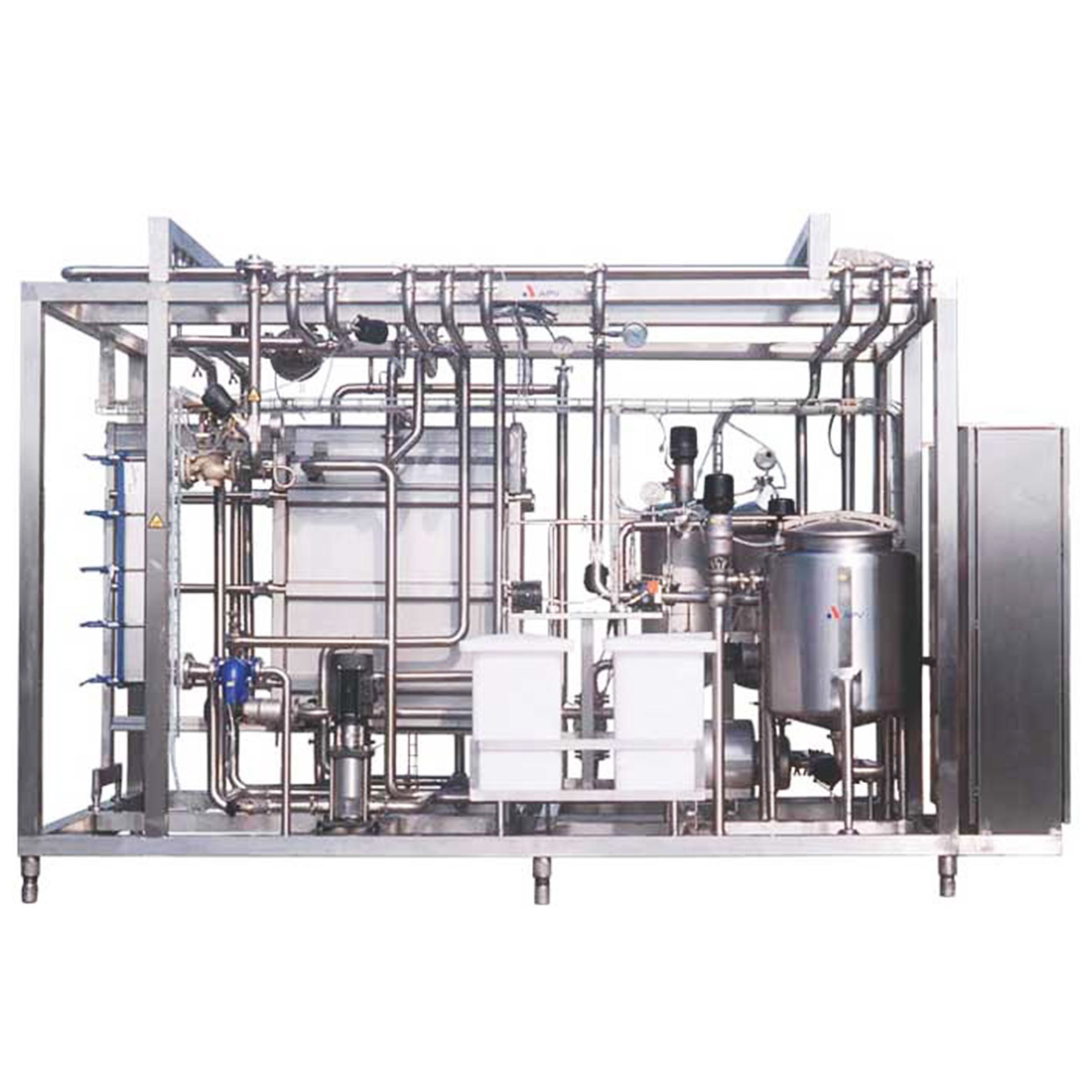

Plate UHT plant - SIH

A UHT plant designed for cost efficient running and a heat regeneration of up to 96%.

The advantages of a SIH Plate UHT plant include:

- High energy recovery, giving low running cost

- Flexible low viscosity product range

- Low pressure drop

- Pare Clip gaskets (non-glue)

- Operator-friendly, pre-assembled and factory-tested

- High energy recovery, giving low running cost

- Flexible low viscosity product range

- Low pressure drop

- Pare Clip gaskets (non-glue)

- Operator-friendly, pre-assembled and factory-tested

Scraped Surface Heat Exchanger UHT plant - SSHE

A UHT plant designed for robust and flexible running of products with very high viscosity for which a tubular or plate UHT plant is not suitable.

The advantages of a SSHE Scraped Surface Heat Exchanger UHT plant include:

- Effective processing of high-viscosity products and products containing particles

- Operator-friendly, pre-assembled and factory-tested

- Effective processing of high-viscosity products and products containing particles

- Operator-friendly, pre-assembled and factory-tested

Pasteuriser Units

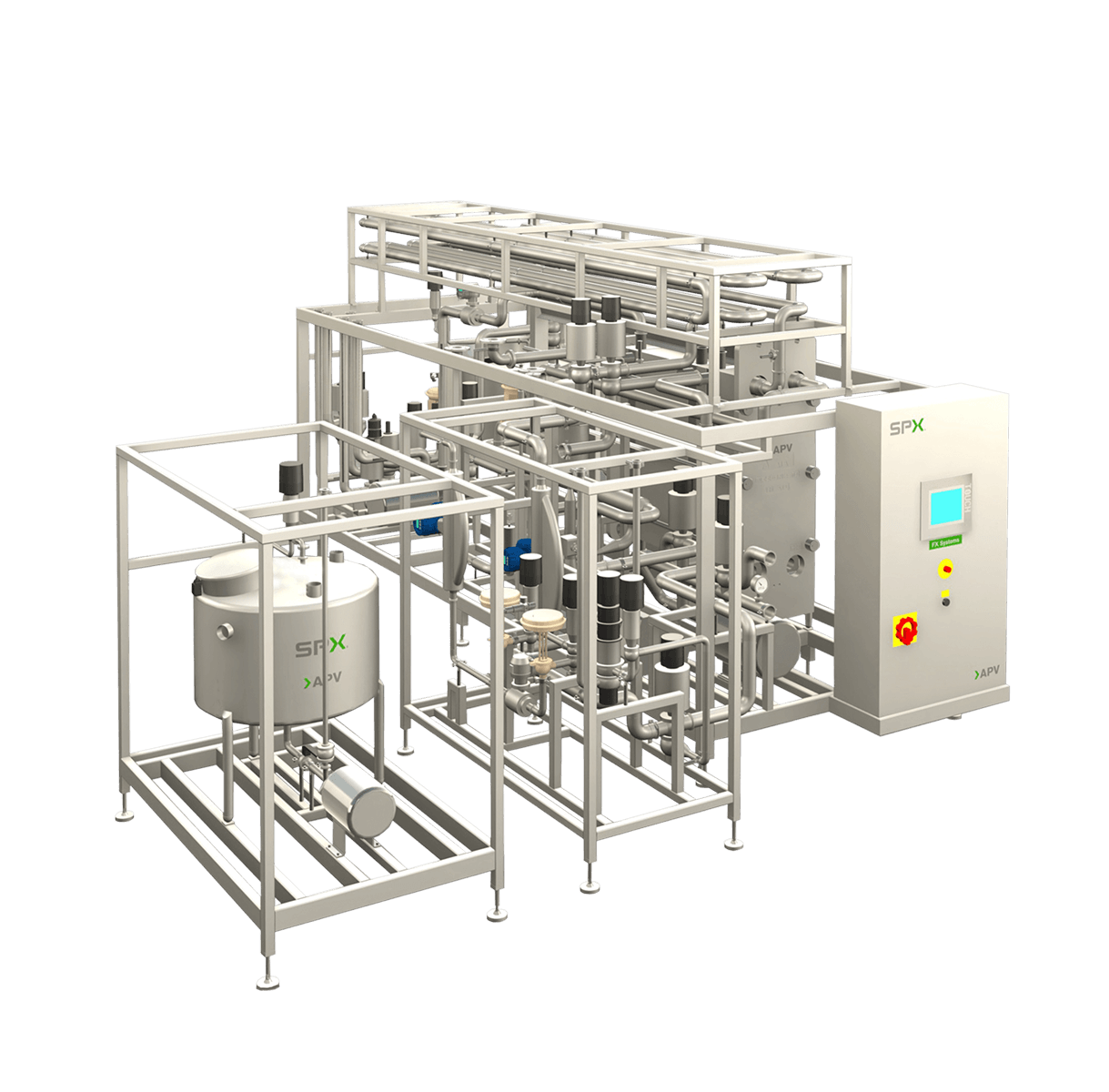

FX Milk Pasteuriser Unit

The FX Milk Pasteuriser can be used for pasteurisation of fresh milk. There is a wide choice of capacity for customer to choose, and customers are able to optimise efficiency and ROI with minimum investment even when full production level is achieved.

The advantages of a FX Milk Pasteuriser Unit include:

- Modular system for complete flexibility

- Simply connect and run

- Automatic control

- Rapid production increase

- Integration with existing control system

- Capacities ranging from 3,800 to 35,000 l/h

- Lower investment costs

- Short pay-back time and high ROI over a long service life

- Pre-assembled and factory-tested

- Modular system for complete flexibility

- Simply connect and run

- Automatic control

- Rapid production increase

- Integration with existing control system

- Capacities ranging from 3,800 to 35,000 l/h

- Lower investment costs

- Short pay-back time and high ROI over a long service life

- Pre-assembled and factory-tested

FX Juice Pasteuriser Unit

The Tubular Juice Pasteuriser can be used for juices, soft drinks, tea and coffee drinks, and water. It can run low-viscosity products as well as fibres and particles. Fully CIP prepared for easier cleaning.

The advantages of a FX Juice Pasteuriser Unit include:

- Modular system for complete flexibility

- Simply connect and run

- Automatic control

- Rapid production increase

- Integration with existing control system

- Capacities ranging from 3,000 to 35,000 l/h

- Lower investment costs

- Short pay-back time and high ROI over a long service life

- Pre-assembled and factory-tested

- Modular system for complete flexibility

- Simply connect and run

- Automatic control

- Rapid production increase

- Integration with existing control system

- Capacities ranging from 3,000 to 35,000 l/h

- Lower investment costs

- Short pay-back time and high ROI over a long service life

- Pre-assembled and factory-tested

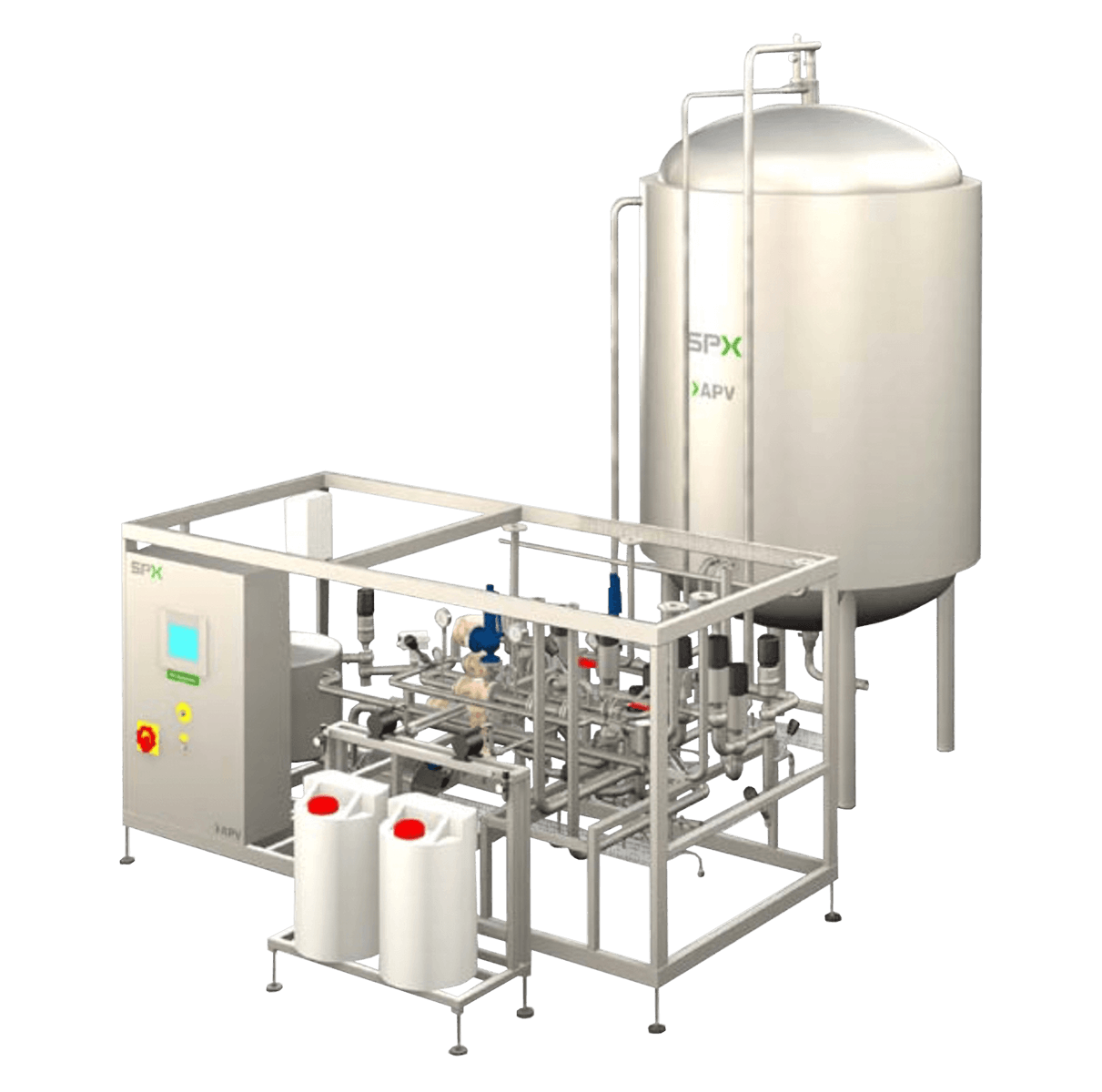

Aseptic Tanks

FX Aseptic Tank

The APV FX Aseptic Tank offers buffering capacity for all UHT-treated liquid aseptic products between the UHT line and filling machines, thus ensuring smooth and efficient continuous production with no loss of product quality or nutritional value.

The advantages of a FX Aseptic Tanks include:

- Engineered solutions transformed into high-performing modules

- Small footprint for installation in spaces too small for other equipment

- Integration with UHT control system or filling machines

- Product changeover without interruption

- Filling line service and repair without stopping UHT plant

- Capacities ranging from 10,000 to 40,000 l/h

- Incoming flow rates from 3,000 to 20,000 l/h

- Short pay-back time and high ROI over a long service life

- Pre-assembled and factory-tested

- Engineered solutions transformed into high-performing modules

- Small footprint for installation in spaces too small for other equipment

- Integration with UHT control system or filling machines

- Product changeover without interruption

- Filling line service and repair without stopping UHT plant

- Capacities ranging from 10,000 to 40,000 l/h

- Incoming flow rates from 3,000 to 20,000 l/h

- Short pay-back time and high ROI over a long service life

- Pre-assembled and factory-tested

Catalogue/ Brochure/ Technical Specification

UHT Portfolio brochure

FX Milk Pasteuriser brochure

FX Juice Pasteuriser brochure

FX Aseptic Tank brochure