Mixing System

Sugar Dissolving System

The Continuous Sugar Dissolving System is a fully automatic sugar syrup blending system, which can readily be integrated with any APV beverage process unit. Capable of producing sugar syrup up to 72°C (162°F) Brix.

The CSD is mainly applied in beverage industry. It features optimum flexibility and great cost saving potential. APEQ Process designs continuous dissolving system based on the APV Flex-Mix series:

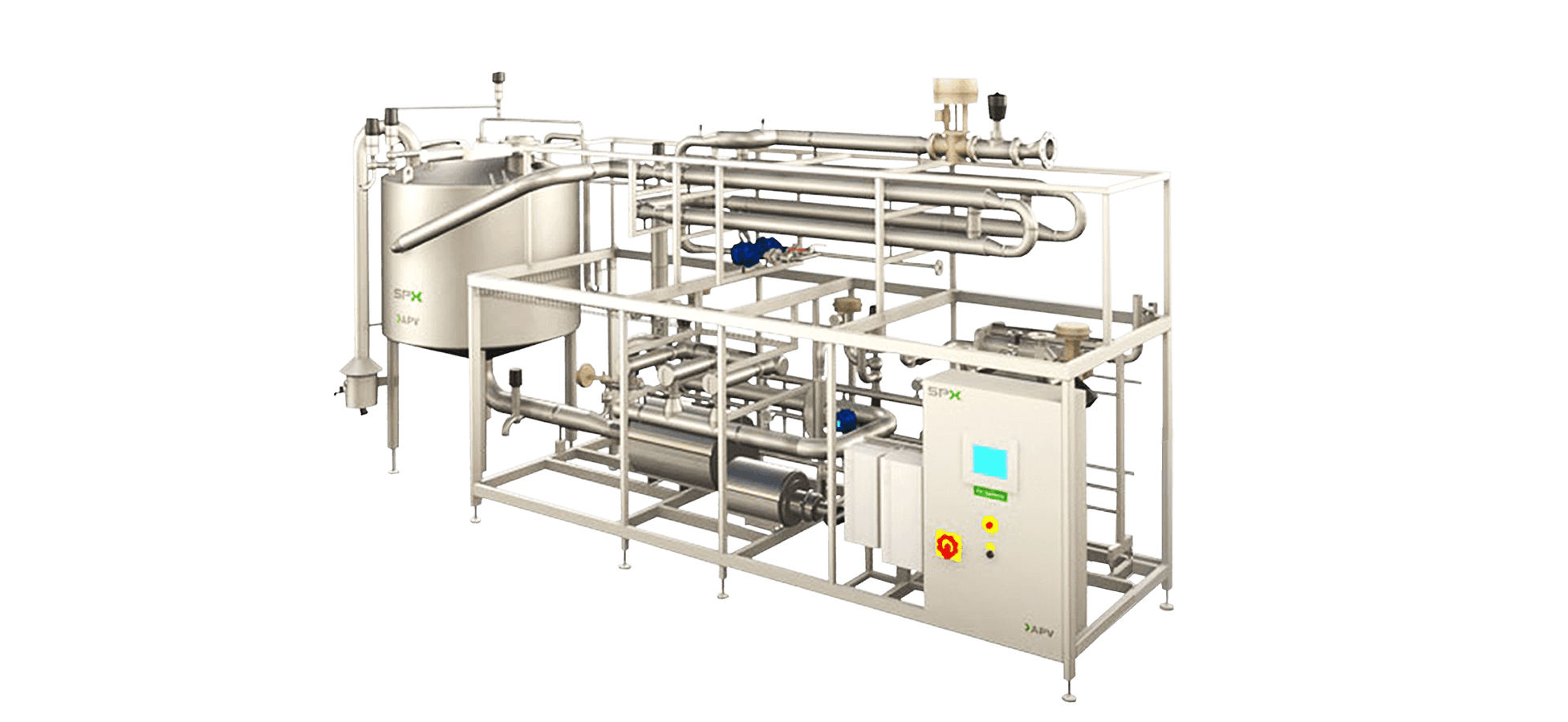

APV Flex-Mix Continuous Sugar Dissolving System

APV Flex-Mix Continuous Sugar Dissolving System

The Flex-Mix Continuous Sugar Dissolving System provides fully automatic Brix control using in-line refractometers or mass flow meters and reduces labour costs and cleaning time through the use of self-cleaning final filters. Continuous Sugar-Dissolver uses the jet mix principle for optimum dissolving and delivers a more precise and consistent product resulting in raw ingredient savings. It is available in capacities ranging from 5,000 to 45,000 kg/h. Featuring the following benefits:

- Fully automatic Brix control

- Lower energy costs via PHE heat recovery

- Easy integration with any SPX FLOW beverage processing solution

- Short pay-back time and high ROI over a long service life

- Modular system for complete flexibility

- Small footprint for installation in spaces too small for other equipment

- Pre-assembled and factory-tested for easy and fast installation

Catalogue/ Brochure/ Technical Specification