Deaerator System

Enhancing Product Quality

and Storability

and Storability

All product processing like pumping and various mixing processes disperse and incorporate air into the mixture. The presence of undesired air and gases in liquid food products frequently leads to deterioration in product quality in physical, chemical and sensory terms.

Air elimination, or deaeration can achieve improved product quality and increase shelf life and storage stability of products. Deaeration also reduces the overall production costs and attains improved process control. Here are the different types of deaeration systems and a selection guide:

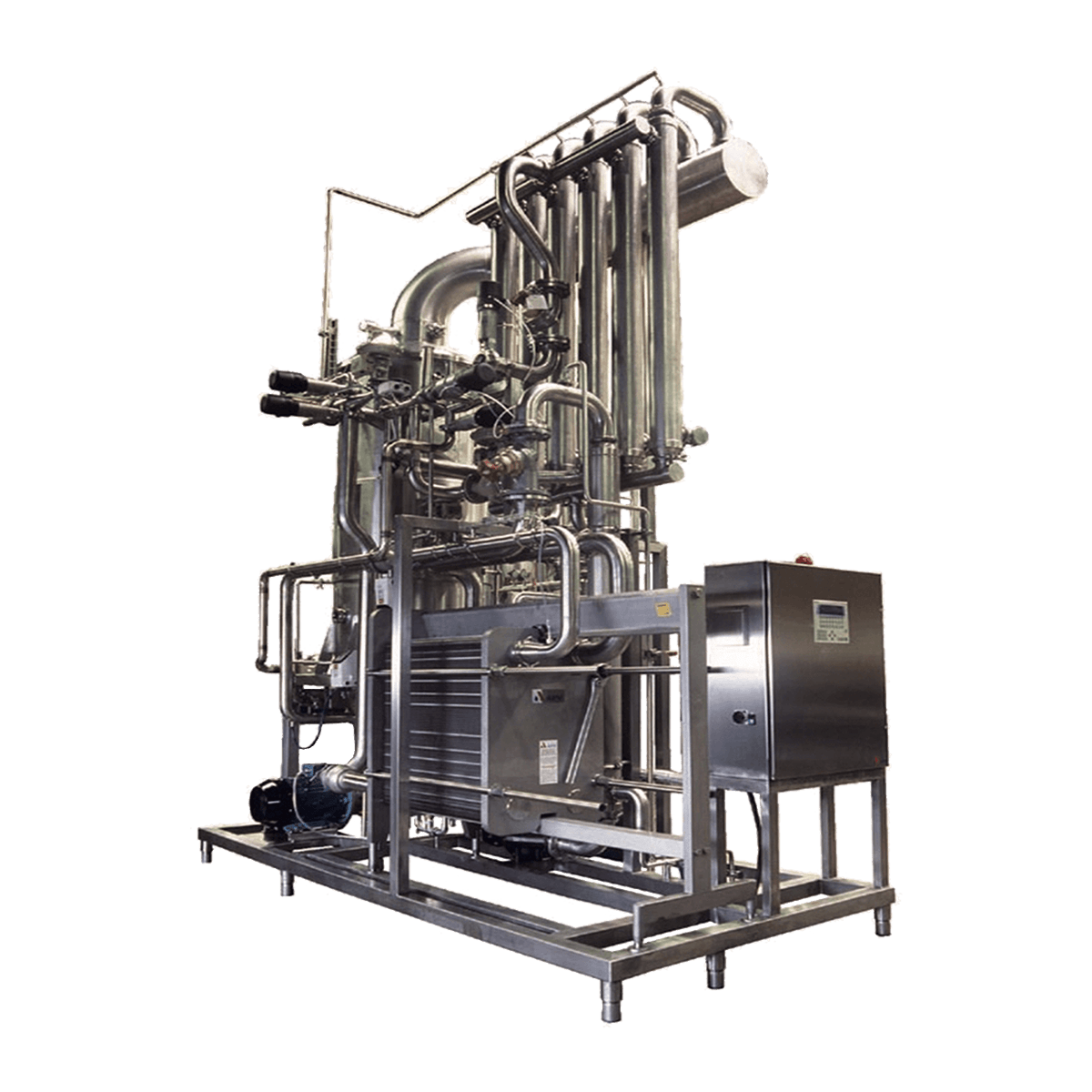

VFJ/ VFN

The deaerators VFJ and VFN include a number of adaptations, including an improved aroma recovery system, designed to meet the demands of both new and existing customers. This modern, optimised processing technique with integrated aroma recovery provides improved retention of colours and volatile flavour components.

The VFJ and VFN Deaerator Systems features the following advantages:

- New, superior aroma-recovery system

- Automatic parasol regulating valve

- Improved hygiene

- Reduced commissioning costs

- Operator-friendly

- New, superior aroma-recovery system

- Automatic parasol regulating valve

- Improved hygiene

- Reduced commissioning costs

- Operator-friendly

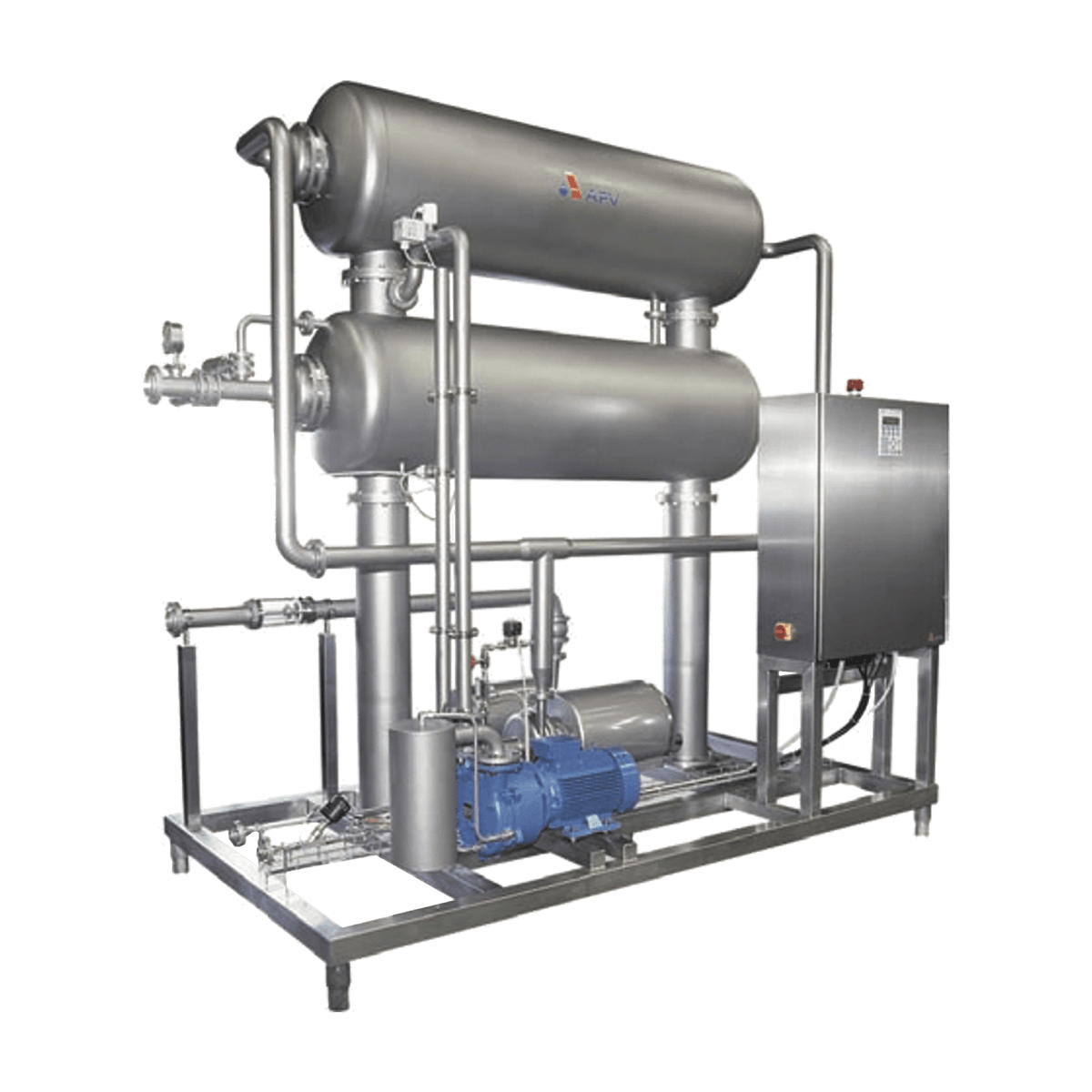

VFN E-VAP Concentrator

The VFN E-VAP is designed to increase total solids by a few per cent by re-circulating the product across the VFN E-VAP unit several times. The VFN E-VAP Concentrator is a stand-alone unit with PLC, enabling the operator to load a recipe with a target set point for the total solids level.

The VFN E-VAP Concentrator System features the following advantages:

- Fresh taste and odour

- Increased viscosity in milk applications

- Smooth and creamy texture in fermented products

- Increased serum stability

- Operator-friendly

- Fresh taste and odour

- Increased viscosity in milk applications

- Smooth and creamy texture in fermented products

- Increased serum stability

- Operator-friendly

Cold Water Deaeration - Derox

Derox cold deaeration achieves low oxygen levels with low capital outlay and running costs.

The Cold Water Deaeration - Derox Deaerator System features the following advantages:

- Constantly low oxygen content of 50 ppb at 12°C (54°F)

- Continuous monitoring for required specification

- Low running costs

- Easy integration with existing lines

- Space-saving design

- Variable capacity and high turn down

- Fully CIP-cleanable

- Constantly low oxygen content of 50 ppb at 12°C (54°F)

- Continuous monitoring for required specification

- Low running costs

- Easy integration with existing lines

- Space-saving design

- Variable capacity and high turn down

- Fully CIP-cleanable

Hot Water Deaeration - Derox+

The Derox+ hot deaeration system heats the water to a high temperature, which reduces the risk of infection and helps remove contaminants

The Hot Water Deaeration - Derox+ Deaerator System features the following advantages:

- Constantly very low oxygen content

- Continuous monitoring for required specification

- Continuous removal of undesirable gases

- Low running costs

- Easy integration with existing lines

- Space-saving design

- Deaerated water is pasteurised

- Fully CIP-cleanable

- Constantly very low oxygen content

- Continuous monitoring for required specification

- Continuous removal of undesirable gases

- Low running costs

- Easy integration with existing lines

- Space-saving design

- Deaerated water is pasteurised

- Fully CIP-cleanable

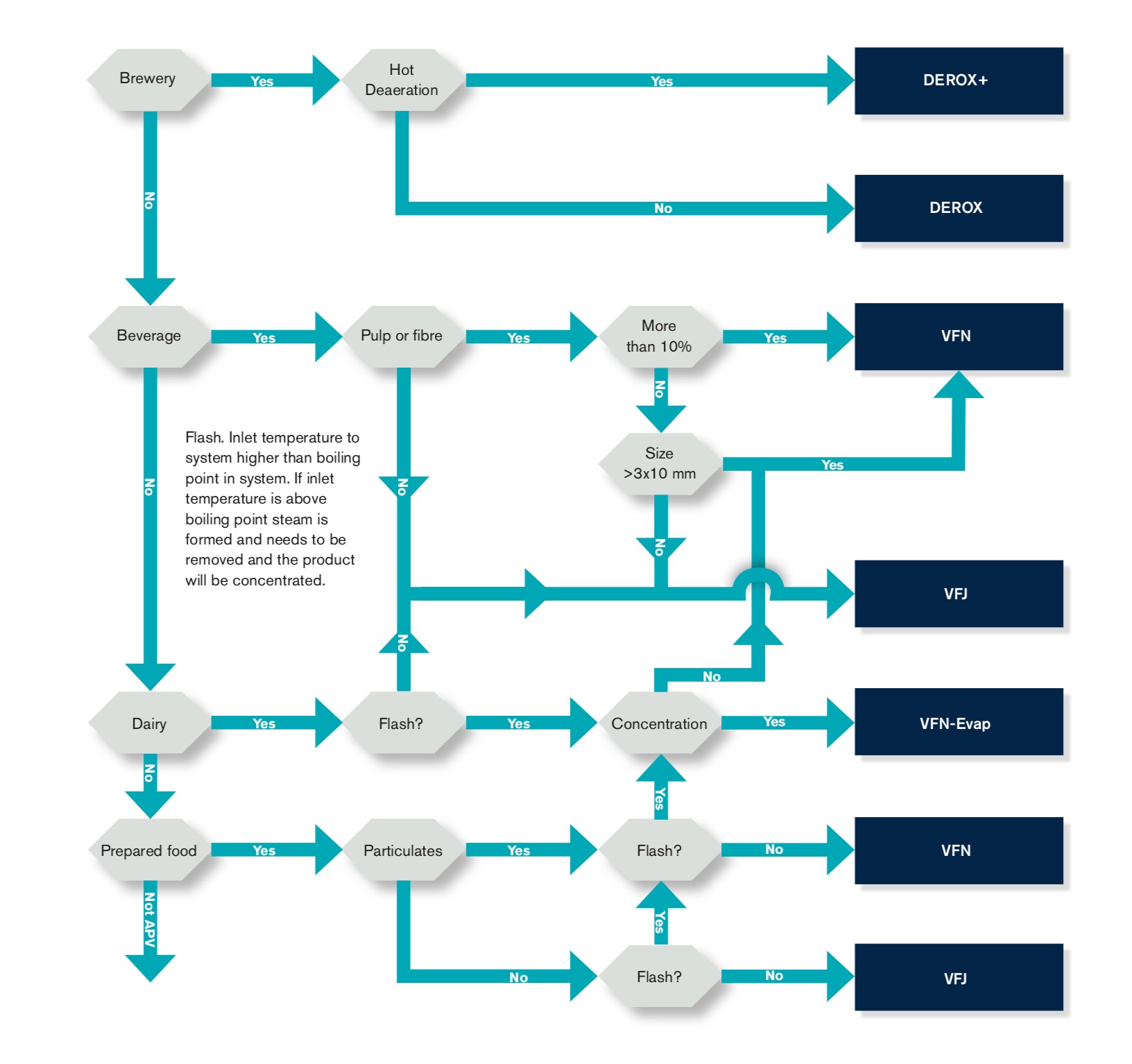

Selecting Deaerators

Different deaerators serve different purposes, and this is where your process objective comes into play.

Whether it is a brewery, a beverage production, or a dairy production, APEQ Process will design a deaerator for you that meets SPX FLOW's global standard.

Whether it is a brewery, a beverage production, or a dairy production, APEQ Process will design a deaerator for you that meets SPX FLOW's global standard.

Catalogue/ Brochure/ Technical Specification