Flottweg® Sorticanter®

Engineered

For Your Success

For Your Success

Environmental protection and recycling are ever greater concerns for companies. As a result, there is a need for new and innovative solutions. This prompted Flottweg to develop the Sorticanter® for processing plastics.

Naturally occurring raw materials such as plants, coal, natural gas and crude oil cannot be recovered from plastics via chemical steps. As a result, recycling plastic is an issue for companies with an environmentalist stance. The Sorticanter® helps contribute to environmental protection according to ecological and economic principles. Applications of Sorticanter® include:

- Processing foils and DSD mixed plastics from packaging materials

- Recycling technical plastics

- Recycling cable sheaths

- Recycling carpet fibres

Turning Waste Into Recyclable Material - Processing Plastics

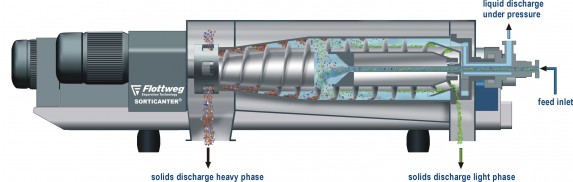

Having materials of a single type is of central importance when it comes to processing plastics (waste, plastic fibres and lightweight packaging). Many plastics differ from one another in density, as a result of which the sink/swim separation process proves to be the most efficient solution for recycling. In this separation process, a separation liquid is used which has a specific weight between those of the types of plastic to be separated. As a result, the "heavy" plastic sinks to the bottom of a container. The "lighter" plastic floats at the surface of the container. The separation process in a container takes place simply using the force of gravity.

In a centrifuge, gravity is replaced by centrifugal force, which has a positive effect on the separation process. The "heavy" and "light" plastics are significantly dryer in a centrifuge than in a container. Furthermore, influencing factors such as air bubbles or dust on the surface of the plastics do not affect the separation process in a centrifuge.

Advantages And Customer Benefits

- - Reduced odour because of a closed system

- - No influence due to the colour of the solids to be sorted

- - Low thermal energy consumption because the dewatering stage (mechanical dewatering) is already integrated in a Sorticanter®

- - Sorticanter® is available as a supplement to the existing system (achieving higher yields, because better purity of grades is achieved)

- - Better product quality, meaning higher value in the end product

- - Operating times of more than 8000 hours per year are the norm

- - Separation of mixed substances that are unsuitable for static separation (fibres)

- - Minimum personnel costs, making for cost savings by the operator

APEQ Process is an official distributor of Flottweg® in Malaysia.

Need a price quotation?

Enquire now >

About Flottweg®

Flottweg® has developed and produced decanters, separators, belt presses, and systems here in Germany for over 60 years. These machines have a reputation of extremely high performance and reliability, and handle key functions in many industries.

Each individual machine that leaves Flottweg®'s Southern German factory embodies their philosophy: Flottweg® want their customers to obtain results with Flottweg® that can't be beaten. Their passion for perfection in detail and in the big picture characterizes Flottweg®'s thoughts and actions.

Catalogue/ Brochure/ Technical Specification

Flottweg - About the Company

Flottweg - Solid Bowl Decanter Technology

Flottweg Sorticanter Brochure and Technical Data