Valve Design

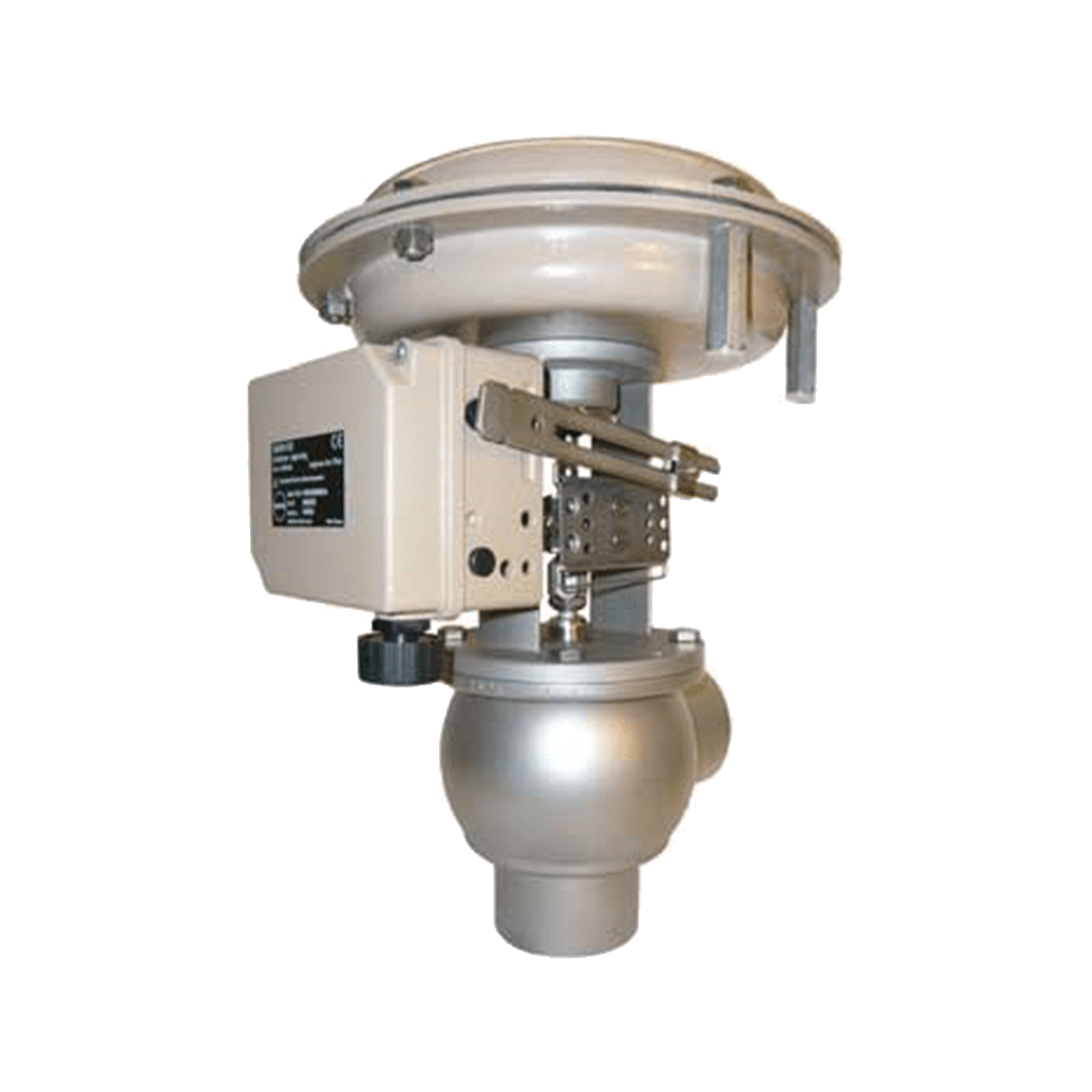

- Optimum clean-ability.

- No stroke limitation by seat lift actuator; the full opening cross section is available during cleaning.

- Very easy to service.

- 3A approved and ATEX compliant

- 3A approved and ATEX compliant

- Profile seals with ID markings that eliminate gaps and facilitate ordering of spares.

- Flexible design for varying Kvs values

- Valve design and testing according to DIN IEC 534.

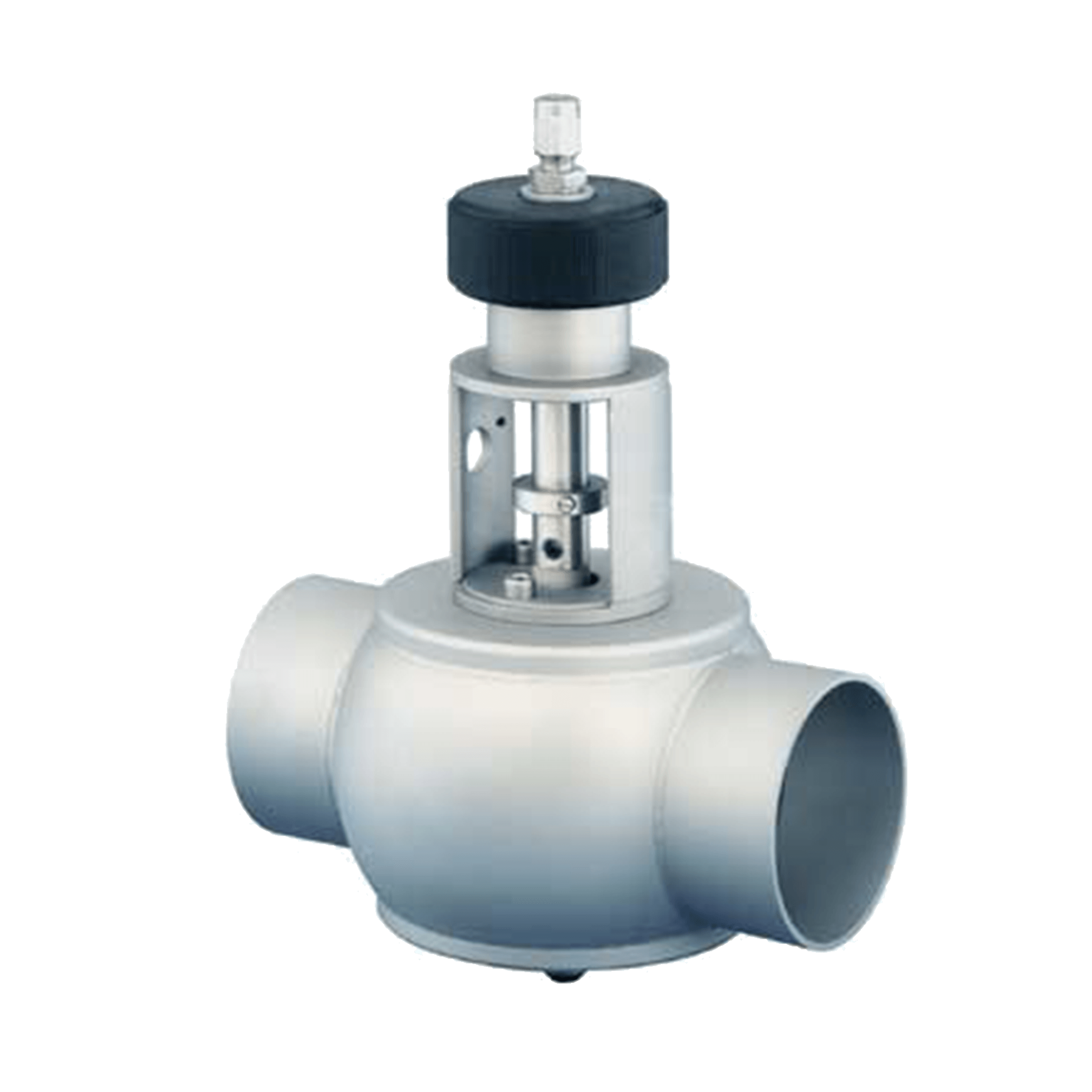

- 3A approved

- Marked profile seals ensuring prompt and safe identification of seal material

- Easy to maintain - the valve insert can be lifted out completely.

- All product contact parts are made of AISI 316L / 1.4404 (DIN EN 100888) stainless steel

- Capable of working in both flow directions (upstream and downstream)

- Precise valve cone control with multi-layer flat diaphragm design (long service life)

- Perfected cleanability – no dead areas, no crevices – fully open valve for sufficient CIP throughput

- All product contact parts are made of AISI 316L / 1.4404 (DIN EN 100888) stainless steel

- Profile seals with ID markings that eliminate gaps and facilitate ordering of spares.

- Easy to maintain - the intermediate flange design means that the valve can easily be removed from the line.

- Flexible design - the valve can be installed horizontally or vertically.

- All product contact parts are made of AISI 316L / 1.4404 (DIN EN 100888) stainless steel

- Prevention of infection thanks to a PTFE shaft and a special shaft guide. No additional seat seal required.

- Cleaning is assured. No dead pockets in the valve body.

- Internal diameter of valve and pipe cross section is identical.

- Problem-free reconstruction from manual to pneumatic operation and vice versa, possible at any time.

- Problem-free integration in an inline system.

- All product contact parts are made of AISI 316L / 1.4404 (DIN EN 100888) stainless steel

- Precise response accuracy

- Gas-tight design

- Maintenance-free pneumatic seat lift actuator for remote function control.

- Optimum clean-ability through ball-shaped housing.

- No shaft guide in product chamber.

- Cleaning of the inside of the housing by a special spray nozzle.

- No dripping or splashing of fluids during cleaning due to a drip tray.

- All product contact parts are made of AISI 316L / 1.4404 (DIN EN 100888) stainless steel

- Hygienic design

- Ideally suited for CIP applications

- All product-contact parts finished to Ra ≤ 0.8 µm.

- Pneumatic or manual operation

- The pneumatic seat lifting device can be equipped with proximity switches for feedback signals.

- Quick and easy seal replacement

- All product contact parts are made of AISI 316L / 1.4404 (DIN EN 100888) stainless steel

- Safety, efficiency, clarity, and reliability at a competitive price

- Ultra bright LEDs for clear indication of valve position, power, and solenoid activation

- High precision position sensors with easy adjustment

- Manual override solenoids and adjustment screw to throttle actuator air flow

- Ability to retrofit and upgrade on existing valves.

All APV Valves Valve Key

APV UF and UFR Relief Valve Brochure

APV UF and UFR Relief Valve User Manual

APV RG4 Modulating Valve Brochure

APV RG4 Modulating Valve User Manual

APV RGE4 Modulating Valve Brochure

APV RGE4 Modulating Valve User Manual

APV CPV Constant Pressure Valve Brochure

APV CPV Constant Pressure Valve User Manual

APV RUF3 Check Valve Brochure

APV RUF3 Check Valve User Manual

APV VPN Check Valve User Manual

APV PR2 Sampling Valve Brochure

APV PR2 Sampling Valve User Manual

APV VRA and VRAH Vacuum Valve Brochure

APV VRA Vacuum Valve User Manual

APV SI2 Safety Valve Brochure

APV SI2 Safety Valve User Manual

APV CU4 Control Units Brochure

APV CU4 Control Units User Manual