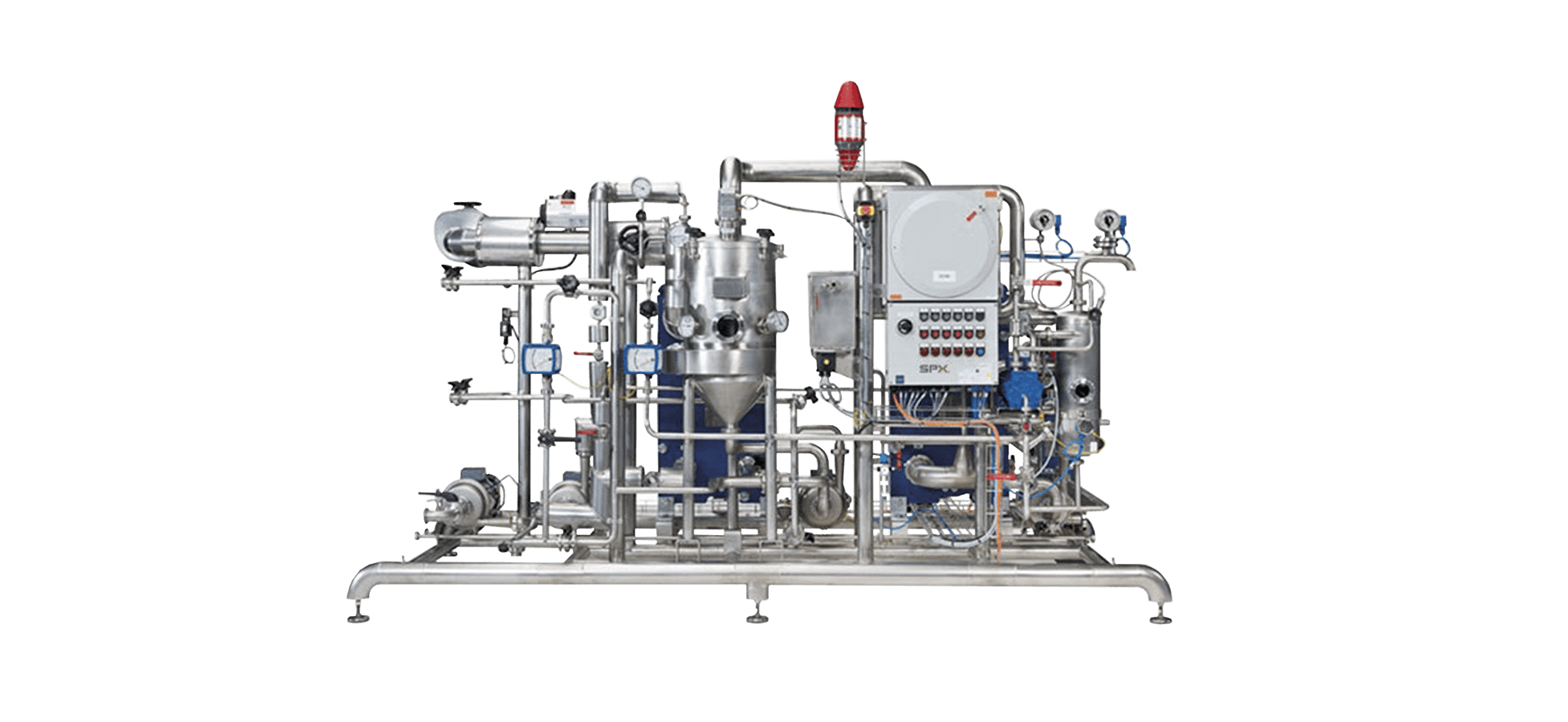

Evaporator System

Economical Energy Utilisation

and Process Effectiveness

and Process Effectiveness

As one of the most energy intensive processes used in the dairy, food and chemical industries, it is essential that evaporation be approached from the viewpoint of economical energy utilisation as well as process effectiveness.

The rising/falling film evaporator has the advantages of the ease of liquid distribution of the rising film unit coupled with lower head room requirements. APEQ Process provides two main design of large-scale falling film evaporators:

Falling Film Plate Evaporators

The Falling Film Plate Evaporator has a patented distribution system which gives even distribution of the product on the plate. This allows for low required wetting rates and easy single pass design.

There are three sizes of plates with water removal capacities ranging from 907 to 27,216 kg/h. Multiple effect or MVR can be utilised due to the very low temperature difference required.

Multiple effect or MVR can be utilised due to the very low temperature difference required.

Rising/Falling Film Plate Evaporators

As the original plate type evaporator, the Rising/Falling Film Plate system is a flexible, multi-duty unit engineered to handle small to medium production runs of heat sensitive products.

Water removal capacities range from 454 to 15,876 kg/h for the standard size plate. For much smaller production or pilot plant trials a “Junior” plate evaporator can operate as low as 45.5 kg/h water removal. Either plate can be arranged in a multiple effect system to maximise thermal efficiency.

Either plate can be arranged in a multiple effect system to maximise thermal efficiency.